In engineering teams we often run into tolerance calculations. We know they’re supposed to help us avoid future out-of-specs and maybe even save some money. But let’s be honest—how many of us actually enjoy doing them? And what is that about having two types of calculations for the same topic?

What is RSS, you ask? And why should we care? Is it really better than the old-school, worst-case method that’s been working “well enough” for years? Worst-Case vs RSS is always a hot debate.

We hear that RSS might give us tolerances that are too optimistic, and that it doesn’t cover all the risks. Besides, our suppliers usually deliver parts that are almost always in spec, right? So, why add complexity with RSS when the worst-case method seems to work fine?

Today, we’re diving into these questions. We’ll explore whether RSS is worth the effort and what exactly sets it apart from worst-case scenarios.

How are you, my friends? Yes, I always like hot topics that engineers get to discuss about, like: Do we really need to use RSS, or is the worst-case method good enough?

This topic has come up time and time again to me for more than 20 years of engineering. It’s like a never-ending discussion. But why is RSS such a sticking point? Ask a statistician or a mathematician, and they’ll tell you it’s a no-brainer. For them, RSS is as easy as pie. So why do we engineers find it tricky?

Today, we’re going to crack this case wide open. We’ll look at the tough spots that make RSS challenging, learn how to argue for or against it, and understand when it truly makes sense to use it. Here’s what we’ll cover:

1. WC vs. RSS: What’s the difference?

2. A real-world example using the Worst-Case method.

3. The same example, but this time using RSS.

4. We’ll analyze the differences.

5. And finally, draw some conclusions and recommendations.

Alright, let’s get started!

- WC vs. RSS: What’s the Difference?

First things first, let’s clear up the fundamental difference between Worst-Case (WC) and Root Sum of Squares (RSS).

At its core, the difference is this: WC is a simple arithmetic sum, whereas RSS is a statistical calculation. You might be thinking, “But, aren’t they both just calculations? What’s the big deal?”

Here’s the thing: WC calculations are just adding numbers together—like stacking blocks. There’s no statistical context or consideration of variability. You just sum A + B = C. It’s straightforward but doesn’t account for how these tolerances might interact in the real world.

On the other hand, RSS takes into account the statistical likelihood of multiple tolerances occurring together. It gives you a more realistic, often more achievable, tolerance range by considering the probability of different variations happening simultaneously.

Let’s move to an example to make this crystal clear.

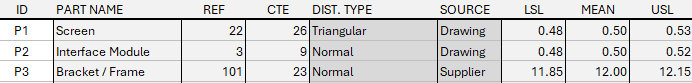

Here’s an Excel spreadsheet snapshot with a simplified example involving the assembly of a car dashboard, specifically the infotainment system. We’ll focus on three main components: the screen, the interface module, and the frame that holds everything together.

We see a column with the distribution type for each item. We don’t care those today, they are there for an eventual RSS 202 or something.

| ID | PART NAME | REF | CTE | DIST. TYPE | SOURCE | LSL | MEAN | USL | Cpk | LEFT VARIATION | RIGHT VARIATION | ΔTMEAN | ΔTTOL |

Leave a Reply